Along the years LIIS has dedicated much of its energy to organizing activities for its students that are alligned to the requirements of the present day technologies and labor market requisites. Our highschool has participated in the ing at the First Tech Challenge competition which is the biggest robotics competition ever made at an international level since 2017 and the awards were not bad considering the lack of practical knowledge that our students experience. Innovations, automatizations and optimizations of processes were no longer news to us.This year, based on the SkyStone theme, every team had to prepare a robot that has to meet many expectations, such as fulfilling requirements with efficiency in a selected amount of time. A match in this competition consists of two periods, the autonomous period, when the robot has to execute a preprogrammed process, and the driver controlled period, when the robot is fully controlled by the two members of the team using gamepads.

Everyday a new idea came out at the school teams departaments including mecanics, programming, 3D design and even marketing. For instance, at the start of this school year, one problem that popped out was the weight of the robot. At FTC, the last 2 years, one requirement that has always created a difficulty for us was the size of the robot. It had to fit certain parameters and we almost failed to meet the demands for the width, lenght and height. To solve this problem, we thought about using wood instead of alluminium bars.

During this pandemic, CyLiis Peppers took their activity online making multiple activities and reaching out to the community by social media and platforms that incoropated video calling. Gathering hope and reuniting teenagers has helped maintain the relationship with the local community.

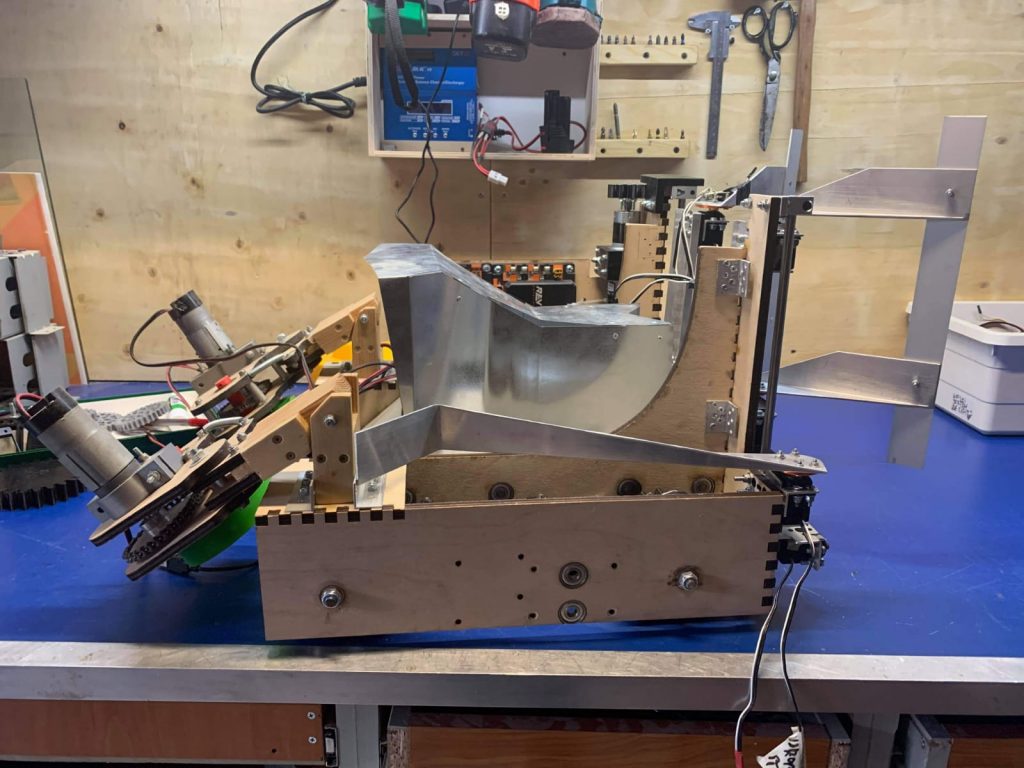

CyLiis Peppers has used encoders to help ease the code of the robot. We wrote a program to interpret and read a file with comands and transform them into encoder steps. For example, a comand like ”go_forward 30” would make the robot go straight ahead by 30 centimeters. The team was awarded an Innovation Award at FTC for using multiple optimised algorithms and systems. For example, the hardest task at FTC this year was placing the ”stones”, which are plastic bricks, one above the other in a tower-like structure so that the height of this tower is as big as possible. To solve this task efficient most of the teams used a lift system and could place as many bricks as the lift’s height allowed. So they thought, what if they could place as many bricks as we want or have. That’s how they were the first team in Romania that implemented the reverse intake system, that system would lift up the tower and place a brick under it while other teams would limit their tower height by their lift’s height. The system is more solid and lasts longer without repairing. Besides this system, they used a circular band similar to the one used in supermarkets for another requirement of the SkyStone theme, placing bricks at an indicated zone.

This year, we thought a lot on making the chassis and the robot with an as-small-as-possible budget. To do that, CyLiis used a chassis made out of wood with a plywood of 8mm, using joints in a comb-like way to stiffen the ensemble, to eliminate any difficulties. When using odometry, the tyres were fixated with bearings in the plywood so that the code would not have any misinformation on the position of the robot in the game field.

As it can be seen, from marketing to mechanics and coding, we have learnt and explored as many optimizations and innovations as possible.